Quality is at the top of our list of priorities. So, when we receive industrial prints from our customers, we take the time and effort to reduce potential issues that may arise in fabrication.

Our engineers have an intimate knowledge of our fabrication floor and how products flow through the cells. They use this knowledge to manage prints for manufacturability—a process that is similar to conducting smaller versions of an FMEA.

Here are a few examples of the methods our engineers error proof customer prints to ensure better quality and decrease the probability of mistakes on the fabrication floor.

Many methods depend on making little, asymmetrical alterations that don't have an effect on the product's usability or aesthetic. This makes it easier for the people on our shop floor to orientate.

- Asymmetry

- Slot-in-tab

- Different holes sizes

- Symmetrical parts so it won't matter if someone forms it backward

- Clip spring-loaded piece symmetrical parts

- Fit to fixture

You can see a few examples of these methods in the following pictures:

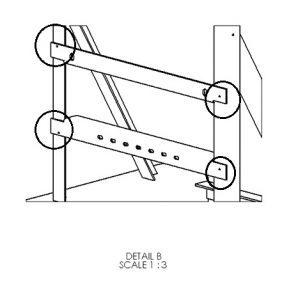

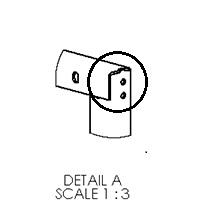

Here's an excellent example of asymmetry and hole sizes. Notice how the holes on the sides are not only on different sides but also vary in distance from the edges.

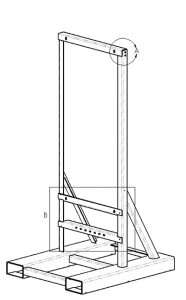

Here's an example of slot-in-tab.

This entire contraption is put together via slot-in-tab—efficiently eliminating a need for fixtures.

Error proofing industrial prints doesn't imply anything to the quality of the pre-existing prints; it just presents a way to improve quality from a manufacturing standpoint by initiating a way for our fabricators to self-check their work.

Do you have an industrial project in mind? Or perhaps a redesign? A question or two? Comment below or contact us today for the industrial product of your dreams.

HUI dedicates itself to helping our customers design the solutions they need and launching quality products on time and within budget.

HUI dedicates itself to helping our customers design the solutions they need and launching quality products on time and within budget.