Continuous improvement should be a big part of every manufacturing company’s culture, so it’s important to find ways to encourage employees to get involved. At HUI, we bring together a lead from each team, who focuses on finding opportunities to make company-wide improvements. However assembling the team is just a start, so we’re going to cover some ideas on how to encourage continuous improvement on the shop floor.

Continuous Improvement Teams

Find Continuous Improvement Supporters

To create an effective team, start by looking for your continuous improvement/lean leaders. Find people who are passionate about improving their area and are willing to put in the extra work. Pick teammates who have a hard time accepting things the way they are, because they will be your most important advocates.

Meetings

Meet with the continuous improvement team regularly to discuss Lean wastes that are brought to their attention, or that they’ve spotted on the shop floor. Determine the 5s projects you’d like to focus on as a team. This meeting also gives everyone a chance to evaluate the improvements made on top-priority projects that are now in the pipeline.

You can also use these meetings as a training opportunity to teach everyone more about continuous improvement. For us, that training is often as simple as a YouTube video explaining different Lean processes.

Audits

Audits and checklists are a good way to help your continuous improvement leads know what they need to look out for on the shop floor. Put together a list of weekly Lean concerns, and determine a scoring system to help the team prioritize what needs to change.

Encourage Continuous Improvement

Weekly Communication

At HUI, we have daily huddles with our teams, where each group gets together to discuss any important information for the day. This gives the continuous improvement leaders a chance to inform their group on new 5S projects and updates on current Lean projects. It’s important to let everyone on the team know what’s going on with Lean initiatives, so they don’t overlook any changes.

Celebrate Wins

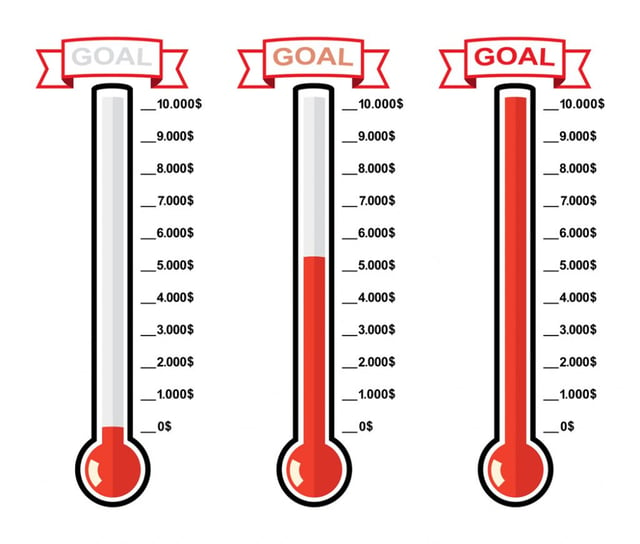

Remind people that change will make their job easier in the long-run. Show them real examples in terms of dollar savings and time savings. We track our progress with a thermometer visual to give everyone an understanding of the true value of all the Lean improvements. Also, make these victories a big deal. Everyone should celebrate and enjoy the savings. It’s not just about making the company more money, but giving everyone a piece of that success. For example, when your teammates reach a goal, you can reward them with giveaways or a pizza party for lunch.

Once your teammates can see the benefits of continuous improvement initiatives, you’ll gain the buy-in you need to make important changes. Although all change takes time and effort, they’ll understand it’s worth it in the long-run, as their job gets a little easier and more optimized every day.

If you have questions for our Lean leaders about how to encourage continuous improvement, please comment below. Also, contact us today if you need help with your own custom industrial project.

To get instant updates anytime we have a new blog post, please click here to subscribe to HUI’s Industrial Manufacturing Blog.

HUI dedicates itself to helping our customers design the solutions they need and launching quality products on time and within budget.

HUI dedicates itself to helping our customers design the solutions they need and launching quality products on time and within budget.