HUI began implementing lean principles in 1998, and from the start, we included the offices in the lean transformation. Though it’s common for companies to implement lean processes on the manufacturing shop floor, it’s easy to see how lean thinking adds value to any work setting. I sat down with the Industrial Business Development (IBD) team to learn more about the lean principles they use today and discover how those principles have influenced their office environment.

Lean Principles in an Office Environment

Cross-Training

IBD cross trains employees on the team, so they can help one another when one of their teammate’s task list becomes overloaded. A mountain of paperwork on someone’s desk is a surefire sign that your teammate has too much on his or her plate. Unfortunately, the cubical layout of your typical office—a layout that HUI once assumed—would hide your teammate’s workload from sight. By removing these interior walls, we’ve maximized verbal and nonverbal communication. Now it’s easier to see and hear when a co-worker needs help.

Seeing Every Step of the Process

Besides knowing what each teammate has in their workload, sitting in an open office allows IBD to see and hear what happens during every step of their teammates’ projects. However, this also gives insight as to how their actions affect everyone on the team. For instance, when someone makes a mistake or finishes his or her task late, that person immediately sees the subsequent effects on the next person in the flow. On that same note, this gives the team the opportunity to speculate the reason for the delay and discuss how they can rectify similar predicaments in the future.

Immediate Communication

Lean principles inspired the company to make communication more efficient. Originally the offices were divided into engineering on one end of the building and customer service and purchasing on the other end. If you needed to ask a question or pass along information, you’d have to walk across the building to the other team, which wasted a lot of time. Now the IBD team has every person involved in the industrial project management process located in the same room.

Problem Solving and Teamwork

Having a complete team of people consisting of every role in the industrial project management process working in one, open office creates a unique dynamic that encourages efficient problem solving. As one of our manufacturing engineers, Chris Freund, explains, “You tend to solve problems based on your own experiences and background. By discussing issues with the whole group, we get ideas outside of our engineering mindsets from people who have different ways of approaching problems and coming up with solutions.” This collaboration is extremely valuable since our management is rarely the one making the final decision. The team is responsible for moving forward with a solution based on their consensus.

Organizational Habits

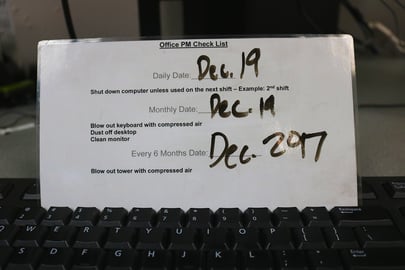

Lean principles have also improved the organizational habits of everyone in the office. Everything that’s placed on each employee’s desk needs to be marked off with tape and labeled, as shown in the picture below. It encourages those in the office to keep their desks organized and really take into consideration what items they use on a regular basis and what items only cause unnecessary clutter. Everyone also keeps a personal maintenance list (also pictured below) to document the last date the computer was shut down and when certain items were cleaned. It starts out as a reminder of company expectations and eventually turns into habitual tasks.

Lean principles have improved HUI’s office environment by creating stronger teams, encouraging quick communication, and inspiring better organizational habits. Companywide our PPM has decreased by 90 percent, lead time has gone down by 71 percent and on-time has improved by 13 percent. If these lean processes can do this much for our office teams, imagine the impact implementing lean principles could have on your company. If you have any questions about our lean processes, or if you would like help getting started with lean strategies, please contact us today.

HUI dedicates itself to helping our customers design the solutions they need and launching quality products on time and within budget.

HUI dedicates itself to helping our customers design the solutions they need and launching quality products on time and within budget.