Choosing a color for your industrial product may not be an exceedingly difficult issue. Many customers already have a custom color scheme that reflects their brand. However, the extensive options for powder coat finishing may throw you through a loop. No worries! Here’s a basic guide on glosses and textures, thanks to our consultant Dan Wolf from Akzo Nobel Powder Paint.

Gloss

Glossy finishes—like a smooth poly-TGIC—are compatible with any chemistry or material. There are four levels of gloss.

Gloss Levels:

1. Matte

- Levels 0-10

- A matte gloss, also known as “flat,” gloss has almost no shine to it.

2. Satin

- Levels 20-40

- A satin gloss is less two-dimensional than the matte gloss but doesn’t have a clear reflective.

3. Medium Gloss

- Levels 40-60

- A medium gloss is a little more reflective.

4. Full Gloss

- Levels 80 or higher

- A full gloss is very shiny and reflective.

You can really tell the differences in gloss finishes in each of these photos from the crispness of the reflections.

Textures

Textures offer a little more visual depth and tangibility to product surfaces. An innumerable amount of textures exists, which are also compatible with any color.

Here’s a few more common textures:

Sand Texture

A sand texture looks similar to sandpaper but cannot be paired with anything above a 20 on the gloss scale.

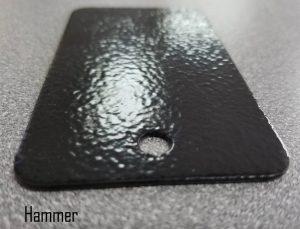

Hammer Texture

A hammer texture looks similar to a golf ball, or an orange rind, and is more likely to be paired with a higher gloss. Keep in mind that the hammer texture will detract from its reflective clarity.

Wrinkle

A wrinkle texture looks similar to the sand texture, except it’s “tighter” and feels rougher. Wrinkle textures are not compatible with glosses.

Below you can see a better visual representation of the difference between a wrinkle and sand texture.

Which option is best for your industrial product?

As sheet metal manufacturers with in-house powder coating capabilities, we’ve noticed a trend in people leaning away from high glosses in favor of textures. High glosses are prone to showing wear and tear, whereas most surface damages are not as noticeable on textures. What kind of environment will your product end up in? You may want to consider a texture if your industrial product is in an environment that it’s likely to collect scuffs, scrapes and dents.

By itself, glosses won’t cover grind marks and scratches that happen throughout fabrication. If you’re considering a gloss finish, there’s a good chance you’ll also need to invest in higher finishing standard. Textures will cover more than glosses and shouldn’t need a higher finishing standard, so it’s more cost effective in the long run.

Do you have an industrial project or powder coating need? HUI has many developed colors in both texture and gloss to choose from for your project, so contact us today. We’re happy to help!

HUI dedicates itself to helping our customers design the solutions they need and launching quality products on time and within budget.

HUI dedicates itself to helping our customers design the solutions they need and launching quality products on time and within budget.