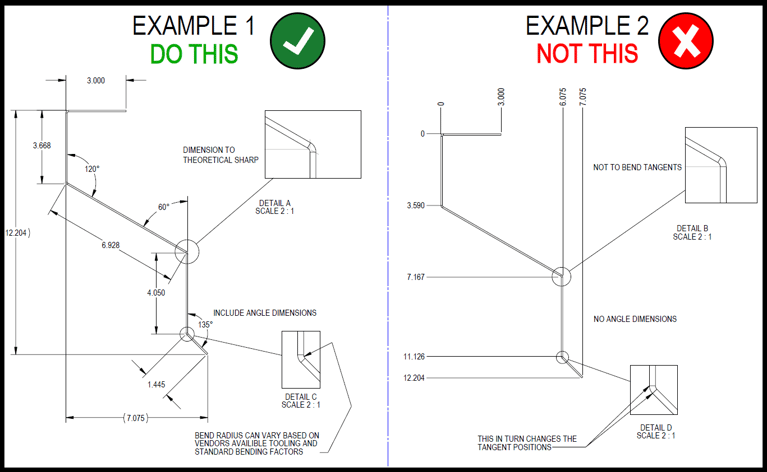

A common problem that may occur when working with an industrial manufacturer is that they will often need to correct dimensioning measurements from your original drawing. Your manufacturer will make these edits so they will be able to model the part and confidently meet the outlined measurements during inspection. However, these corrections require extra time and labor cost to keep the project moving forward. To help you prevent these common dimensioning mistakes we’ve put together some reference pictures and information to help you understand the correct dimensioning information to give your manufacturer.

Manufacturing Blog Manufacturing Blog, Custom Enclosures, Design Engineering, Dimensioning, Industrial, Industry Insights, Manufacturing, Midwest Manufacturers, Press Brake, Sheet Metal Fabrication

The decisions you make about the bend radius during the design stage will determine how difficult it will be to produce the design. That’s why it is important to understand the material’s capabilities and what you should avoid designing around a bend, so you can avoid common press brake design mistakes before the design goes into production. The following list explains four common bend radius mistakes, and how to prevent them.

Manufacturing Blog Manufacturing Blog, Design Engineering, Industrial, Industry Insights, Manufacturing, Midwest Manufacturers, Press Brake, Quality, Sheet Metal Fabrication, Standard Enclosures

When creating a new custom enclosure take time to consider which parts, or hardware, you can share between designs. For example, if one preexisting design has specific studs or latches, you might use the same ones for multiple enclosures when appropriate. Designing with intentional commonalities can benefit both you and your customers, and here’s why.

Manufacturing Blog Manufacturing Blog, Custom Enclosures, Design Engineering, Electrical Enclosures, Industrial, Industry Insights, Manufacturing, Midwest Manufacturers, Powder Coating and Finishes, Quality, Sheet Metal Fabrication, Standard Enclosures

Modifying Standard Enclosures vs. Custom Enclosures: What’s the Right Option for You?

Are you having a hard time deciding whether you should modify a standard enclosure or have a new custom enclosure built for your industrial redesign project? Here’s some information to help you choose the right option for your needs.

Manufacturing Blog Manufacturing Blog, Custom Enclosures, Design Engineering, Electrical Enclosures, Industrial, Industry Insights, Manufacturing, Midwest Manufacturers, Powder Coating and Finishes, Quality, Sheet Metal Fabrication, Standard Enclosures

Each manufacturer has different powder coat paint specification standards. Be sure to discuss your manufacturer’s specification options before you place an order, so you can gain a better understanding of the paint quality your product will receive.

Manufacturing Blog Manufacturing Blog, Industrial, Industry Insights, Manufacturing, Midwest Manufacturers, Powder Coating and Finishes, Quality, Sheet Metal Fabrication

When working with a manufacturer, it’s important to understand your options when it comes to surface finishing standards. If you leave your finishing expectations up to your manufacturer to decide, you’ll end up paying for parts that are overpriced because they’ve been over processed. On the other hand, you could also receive parts that are under processed and have to be reworked. The following guidelines will help you communicate your finishing needs, so you can cut costs on your industrial products.

Manufacturing Blog Manufacturing Blog, Custom Enclosures, Industrial, Industry Insights, Manufacturing, Midwest Manufacturers, Powder Coating and Finishes, Quality

How will an ISO 9001 Certification Benefit Your Industry?

Sometimes the toughest thing about obtaining your 9001 ISO certification is getting everyone in your company on board. It’s a common misconception for many organizations to assume obtaining an ISO certificate will add waste or that the time spent initiating the process won’t pay off in the long run. While it’s true that it takes a lot of hard work to get the ball rolling, an ISO certification is definitely value added to your business in the long run.

Lean Management: 5 Ways to Optimize Fabrication Flow

Countless manufacturers have increased cash flow, lowered PPM and shortened lead times by implementing LEAN strategies and optimizing the flow of their fabrication floor. Most, if not all, manufacturers know that there’s always room for improvement, which begs the question: where do you start?

Supply Chain Management: What to Do When Your Supplier Isn't Performing to Your Standards

We’ve all encountered difficult customer and supplier partnerships. Whether there’s a gap in communication or a recurring quality issue, supply chain managers have the responsibility of determining when enough is enough. After all, we can’t control the actions of others, but we can determine how to best approach the situation.

Manufacturing Blog Manufacturing Blog, Industry Insights, Supply Chain Management

Benefits of Hiring Engineers with Fabrication Experience

Almost all engineers have gone through postsecondary education, but perhaps one of the most beneficial educational experiences is actually working on the shop floor.

Manufacturing Blog Manufacturing Blog, Engineering, Industrial

HUI dedicates itself to helping our customers design the solutions they need and launching quality products on time and within budget.

HUI dedicates itself to helping our customers design the solutions they need and launching quality products on time and within budget.